All published articles of this journal are available on ScienceDirect.

Evaluating Risk Factors of Health and Safety Practices for Managing Hazardous Chemicals in a Fuzzy Environment: A Case Study of Saudi Hospitals

Abstract

Introduction

The health and safety practices while managing hazardous chemicals play a vital role in managing work effectively without any accidents that could lead to injury or death. Various chemicals used in hospitals for maintaining patient health must be handled in a manner that ensures regulatory compliance to prevent any spillage, ingestion, or fires that could put patients' lives in danger.

Objectives

The present research aimed to evaluate the risk factors associated with managing hazardous chemicals in hospitals, considering health and safety practices.

Method

In this study, we employed a fuzzy evaluation approach and carried out an empirical analysis. A questionnaire survey was conducted to determine the critical level (CL) of various identified factors and sub-factors.

Results

The seven factors identified with their CL were organizing and planning (4.02), chemical hazard identification (3.98), risk evaluation (3.97), control measures (4.01), development of safe activity procedures and provision of training on control of chemical hazards (3.97), creation of a comprehensive plan that includes all procedures, controls, and emergency response actions (4.00), and regular inspection of the site to ensure control measures are effective and adhered to (4.02).

Discussion

The CL obtained using the fuzzy synthetic evaluation (FSE) is an important aspect for hospital administration to plan effective strategies. The mean CL of 4.0, with a maximum of 4.02 and a minimum of 3.97, indicates very low variability, suggesting consistent management performance across the measured factors.

Conclusion

The low variability in CL indicates consistent management performance across all factors. The factors with low CL raise concerns for hospital management in handling hazardous chemicals in hospitals.

1. INTRODUCTION

Chemical risk is a growing concern as an occupational exposure when using chemicals in various departments of a hospital. Hospital professionals are directly or indirectly involved in handling hazardous chemicals while performing their day-to-day activities. Thus, health professionals and related staff experience a negative impact on their health and quality of life due to handling hazardous chemicals. Acute and chronic exposure to compounds like formaldehyde, organic solvents, anesthetic gases, etc., may damage their nervous, hematopoietic, or reproductive systems. The hospital safety program should adhere to the most recent regulations set forth by the Occupational Safety and Health Administration (OSHA). The requirement for written plans for handling hazardous chemicals, carrying out risky tasks, and addressing other possible safety issues is one of the primary objectives of the OSHA rules. Furthermore, as per the law of the management of chemical substances, Royal Decree No. M/38 issued on July 12th, 2006, provides Article 1 on the management of chemical substances, chemical waste, long-term storage of chemical substances, and hazardous chemical substances. The chemical substances that are toxic, explosive, or contain properties hazardous to human and animal health or the environment must be handled systematically. In Saudi Arabia, the Ministry of Health oversees hospital standards, while the Saudi Food and Drug Authority (SFDA) supervises pharmaceuticals and chemicals. International laws, particularly those from the US and Europe, form a significant foundation for Saudi Arabia's occupational safety and health requirements.

Thus, the health and safety practices in managing hazardous chemicals in hospitals play a significant role in maintaining the safety of both hospital employees and patients. Hospital employees are at varying degrees of risk when handling different types of chemicals while treating patients in the hospital. The laboratory staff, doctors, nurses, equipment technicians, and others are under constant threat while carrying out various activities that involve hazardous chemicals. Education and knowledge of hospital employees regarding health and safety practices are essential to manage their activities without concern. The health and safety practices followed by hospital professionals must, therefore, be gauged to evaluate the criticality of various factors that pose risks to their lives while handling hazardous chemicals [1]. Considering the above risks, it is very important to evaluate the factors affecting health and safety practices in managing hazardous chemicals. There is a lack of studies examining such evaluation and assessment under fuzzy environments; hence, to bridge this gap, the following research question may be proposed:

RQ1: What are the various health and safety practices among hospital professionals in managing hazardous chemicals?

RQ2: How can various main factors and sub-factors for health and safety practices in managing hazardous chemicals be modeled using fuzzy synthetic evaluation (FSE)?

2. LITERATURE REVIEW

Managing hazardous chemicals in a hospital setup requires proper training and knowledge. Hazardous chemicals, if mishandled, may lead to fatal accidents. Systematic health and safety practices must be followed while handling such chemicals. The following sections provide a comprehensive review of the literature on various aspects of health and safety practices in a hospital setting:

2.1. Studies on the Safety and Health Risk Associated with Hazardous Chemicals in the Laboratories

A study was conducted to investigate the health and safety practices in the laboratories of Oromia Regional State of Ethiopia [2]. It was based on a self-administered structured questionnaire and observation checklists. The investigation focused on the use of biosafety labels, microbial hazards, chemical hazards, physical/mechanical hazards, personal protective equipment, first aid kits, and the waste disposal system in ten randomly selected public hospital laboratories. Another study investigated the chemical risk and safety awareness, perception, and practices among research laboratory workers in Italy [3]. The study assessed the occupational exposure to hazardous chemical substances among research laboratory workers by examining their awareness and perceptions regarding chemical hazards. It also investigated the adherence to guidelines on the safe handling of chemical compounds. Another study was carried out to develop and implement a chemical risk assessment method to determine and prioritize hazardous chemicals in the academic laboratories [4]. This study involved a case series conducted at five academic laboratories and research facilities within an Iranian medical sciences university. The study revealed adequate security provisions and procedures in academic laboratory operations.

2.2. Studies on the Safety and Health Risk of Hazardous Chemicals to Health Professionals

Hospital chemical exposures have been linked to several detrimental health outcomes, such as increased cancer risk, reproductive issues, dermatological ailments, and respiratory disorders. The health and safety conditions of Hungarian hospital nurses were studied [5]. The study revealed that the use of safety measures could protect against occupational exposure at work sites handling cytostatic drugs, anesthetic agents, and sterilizing gases. The effects of improper hospital waste management on occupational health and safety were examined [6]. The study provides several recommendations based on its findings, such as to observe exposure limits, apply a hierarchy of controls, enforce medical waste management regulations, promote training in hospitals, improve waste management and environmentally preferable purchasing, provide proper worker and equipment decontamination, and hold more medical surveillance programs for health care workers.

The status of occupational health and safety (OHS) among health service providers in hospitals in Tanzania was examined [7]. The study was based on a self-administered questionnaire randomly distributed to the health service providers (HSPs) working in 14 district, regional, and referral hospitals in Tanzania. The study recommended training, exposure to information, and promotion of awareness to improve OHS. Based on the National Institute for Occupational Safety and Health (NIOSH) guidelines for health and safety practices, a survey was conducted among healthcare workers to assess their training and awareness of employer safety procedures [8]. Twenty-one healthcare professional practice organizations collaborating with NIOSH were approached to develop and implement the web-based survey. The study recommends training and standard operating procedures (SOPs) to minimize exposure to various chemicals, promote worker safety awareness, and ensure safe handling practices. A survey of safety practices among hospital laboratories in Oromia, a regional state in Ethiopia, was conducted [2]. A cross‐sectional study on occupational exposures to hazardous chemicals and agents among healthcare workers was undertaken in Bhutan [9]. The study was conducted among healthcare workers in three hospitals in the western region of Bhutan. The study revealed that workers were occupationally exposed to chemicals linked to chronic diseases, with the prevalence of exposure higher than in high‐income countries.

2.3. Studies on the Safety and Health Risk of Hazardous Chemicals in General Hospitals

Chemical risk is a major risk factor affecting health professionals while they carry out their daily activities. A study revealed various aspects of chemical risk assessment considering the regulatory and monitoring factors [10]. A systematic review was conducted using the Preferred Reporting Items for Systematic Reviews (PRISMA) and Meta-Analyses review strategy, related to occupational health and safety, conducted between January 2000 and January 2019, using MEDLINE (Ovid), PubMed, PMC, TOXLINE, CINAHL, PLOS One, and AccessPharmacy databases [11]. A study examined the chemical hazards in Saudi hospitals, considering various aspects of risks, regulations, and protective measures [12].

2.4. Use of Fuzzy Synthetic Evaluation (FSE)

The Fuzzy Synthetic Evaluation (FSE) method can be used to assess risk and is particularly effective at handling uncertainty. FSE has been utilized in developing a risk assessment model for Public-Private Partnership (PPP) projects in China to facilitate the implementation of automation in construction [13]. The FSE was used in the analysis of reservoir water quality for stochastic environmental research and risk assessment. The FSE of disinfection by-products was used in developing a risk-based indexing system [14]. A risk assessment based on the FSE was conducted in the coastal area of Bangladesh using the FSE [15]. The FSE has been used to evaluate the factors affecting health and safety practices in the Malaysia construction industry [16]. The FSE was also employed in selecting a location for a logistics facility in Chongqing, China [17]. The FSE approach has been employed for risk assessment in evaluating a case of Singapore’s green projects [18].

However, a study on the health and safety practices in handling hazardous chemicals in hospitals under a fuzzy environment using the FSE approach has not been found. Thus, there is a research gap in investigating health and safety practices related to the handling of hazardous chemicals in hospitals.

3. RESEARCH METHODOLOGY

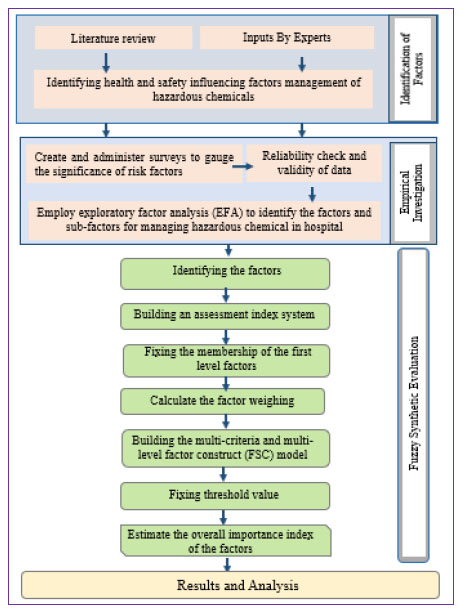

The present research employs a mixed-methods approach, combining quantitative and qualitative methods. depicts the research framework (Fig. 1). Based on the detailed literature, health and safety factors were identified. The questionnaire was developed according to expert opinion and consisted of seven constructs, comprising a total of 23 elements. The administered questionnaire was structured into two parts, with the first part used for descriptive analysis, and the latter containing closed-ended questions for data collection. The second part focused on conducting a risk assessment of hazardous chemicals in the Saudi hospitals. A pilot study of the questionnaire was conducted to assess its feasibility, reliability, and validity before conducting the main study. Four academicians and six hospital professionals were involved in the pilot testing. It helped in identifying two errors in the questionnaire wording. After due correction, using social media and personal contacts, 390 questionnaires were administered to various technical and non-technical hospital staff in Saudi Arabia. Respondents were asked to provide their degree of agreement with the health and safety practice factors in managing hazardous chemicals in the hospital. A five-point Likert scale, with 5 denoting “very significant” and 1 indicating “not significant,” was used. A total of 234 responses were gathered, and after filtering, 14 responses were found to be incomplete. Thus, 220 responses (a response rate of 56.41%) were further taken into consideration for FSE. Fig. (1) presents the framework of the study.

3.1. Exploratory Factor Analysis

Exploratory factor analysis (EFA) is one of the important statistical techniques employed in multivariate statistics to reveal the underlying structure of several multiple factors under observation. EFA helps classify or eliminate the observed factors. Furthermore, EFA helps reveal the underlying structure between observed factors or sub-factors [19].

3.2. Fuzzy Synthetic Evaluation

FSE is employed when an objective assessment of data is quantified using fuzzy set theory, with a linguistic form of input data [18]. The accuracy in decision-making can be achieved through the process of fuzzification and defuzzification. When it comes to decision-making made by various decision-makers (DMs) or experts [20], the FSE approach for analyzing multiple options helps remove ambiguity and erroneous information. According to a study [20], the FSE approach for risk assessment typically follows these steps:

Research framework.

- Identification of main factors and sub-factors;

- Building a fuzzy-based assessment index system;

- Defining the membership functions of the factors and sub-factors;

- Determining the weighting functions of the factors and sub-factors;

- Generating the FSE model; and

- Calculating the overall importance index of the factor constructs.

4. ANALYSIS OF RESULTS

4.1. Respondent Profile

The collected data were analyzed, and descriptive statistics for the respondents are presented in Table 1. The health professionals represented a wide range of job roles. The years of experience and educational qualifications of the health professionals were recorded using descriptive statistics.

| Position in the Hospital | Frequency | Percentage (%) |

|---|---|---|

| Practicing doctor | 25 | 11.36 |

| Nurses | 38 | 17.27 |

| Pharmacist | 26 | 11.82 |

| Laboratory technician | 28 | 12.73 |

| Laboratory attendant | 19 | 8.64 |

| Store staff | 26 | 11.82 |

| Store helpers | 30 | 13.64 |

| Safety personnel | 28 | 12.73 |

| Year of experience | ||

| 1–5 years | 65 | 29.55 |

| 11–15 years | 47 | 21.36 |

| 16–20 years | 44 | 20.00 |

| 6–10 years | 46 | 20.91 |

| Over 20 years | 18 | 8.18 |

| Academic background | ||

| MBBS | 25 | 11.36 |

| BSc nursing | 38 | 17.27 |

| BSc pharmacy | 26 | 11.82 |

| BSc in medical laboratory technology | 28 | 12.73 |

| Certificate programs in lab technology | 19 | 8.64 |

| College graduates | 26 | 11.82 |

| School pass out | 30 | 13.64 |

| Diploma in safety | 28 | 12.73 |

4.2. Analysis of Exploratory Factor Analysis

The Kaiser–Meyer–Olkin (KMO) measure and Bartlett’s test of sphericity were performed to assess sampling adequacy as part of the exploratory factor analysis (EFA). Bartlett’s test of sphericity, a measure of the strength of the link between variables, verified the validity of factor analysis. The results were determined to be significant (χ2 = 2,254.697). The sample size was sufficient to evaluate the factor structure, as indicated by the KMO measure of sampling adequacy, which yielded a value of 0.706 for the parameter. Additionally, the data passed Bartlett’s test of sphericity, proving that they were suitable for factor analysis [21]. The collected data demonstrated a Cronbach's Alpha of 0.786, and even after removing an item, the value remained higher than 0.750 for all variables, confirming good reliability. Furthermore, all the variables were found to be significant at a 99% confidence level, indicating that the data's validity is excellent.

4.3. Fuzzy Synthetic Evaluation Technique

4.3.1. Identification of Factors and Sub-factors

Table 2 provides the factor constructs (FSCs). The factors (FS) in the FSC have dual objectives; hence, they are grouped into two constructs: (i) to identify the input variables for managing hazardous chemical risk assessment and (ii) to find the respective crucial factor in its management.

| Factor code | Factors (FS) with their construct (FSC) | Mean of FS | Total mean of FSC | Weighting of FSs wFSi | Weighing of FSCs wFSCi |

|---|---|---|---|---|---|

| FSC1 | Organizing and planning | ||||

| FS11 | Construct a task force comprising safety personnel and medical professionals | 4.08 | 0.339 | ||

| FS12 | Identify the specific locations in the hospital that involve the handling of hazardous chemicals | 4.05 | 0.336 | ||

| FS13 | Collection of information, for instance, about material handling equipment and chemical properties | 3.92 | 12.05 | 0.325 | 0.144 |

| FSC2 | Chemical hazard identification | ||||

| FS21 | Inspecting and visualizing the areas to identify the risks involved in handling hazardous chemicals | 4.02 | 0.336 | ||

| FS22 | Identification of all locations that may pose challenges to human life | 3.97 | 0.332 | ||

| FS23 | Identifying the properties of hazardous chemicals subjected to improper storage and handling | 3.96 | 11.95 | 0.331 | 0.142 |

| FSC3 | In situ inquiry of possible hazards in chemical handling by professional staff | ||||

| FS31 | Risk evaluation | 4.01 | 0.337 | ||

| FS32 | How likely each identified chemical hazard is to occur, depending on mishandling, poor storage practices, exposure time during use, etc. | 3.96 | 0.332 | ||

| FS33 | Assess the potential consequences of each chemical hazard, such as chemical reactions, fires, and chemical exposure | 3.94 | 11.91 | 0.331 | 0.142 |

| FSC4 | Ranking of the hazards with reference to their likelihood and severity to prioritize which risks need immediate attention | ||||

| FS41 | Control measures | 4.07 | 0.338 | ||

| FS42 | Where possible, remove the source of the chemical hazard | 3.97 | 0.330 | ||

| FS43 | Implement physical changes to reduce risks by modifying storage and handling procedures | 3.99 | 12.03 | 0.332 | 0.143 |

| FSC5 | Develop safe activity procedures and provide training on the control of hazardous chemicals | ||||

| FS51 | Ensure health professionals use appropriate personal protective equipment (PPE) | 4.02 | 0.338 | ||

| FS52 | Documentation and communication | 4.01 | 0.337 | ||

| FS53 | Record the identified hazards, risk evaluations, and the control measures implemented | 3.88 | 11.90 | 0.326 | 0.142 |

| FSC6 | Create a comprehensive plan that includes all procedures, controls, and emergency response actions | ||||

| FS61 | Inform all health professionals about the identified hazards and the safety measures in place | 4.03 | 0.336 | ||

| FS62 | Implementation and monitoring | 4.02 | 0.334 | ||

| FS63 | Put the identified control measures into practice, ensuring all necessary changes are made on-site | 3.96 | 12.01 | 0.330 | 0.143 |

| FSC7 | Regularly inspect the site to ensure control measures are effective and adhered to | ||||

| FS71 | Establish a system for reporting hazardous incidents and near misses to improve safety practices continually | 4.09 | 0.340 | ||

| FS72 | Continuous improvement | 4.02 | 0.334 | ||

| FS73 | Review the risk assessment procedure on a continuous basis to address new incidents, dangers, or regulatory changes | 3.93 | 12.05 | 0.326 | 0.144 |

4.3.2. Formation of an Evaluation Index Structure

The applications of FSE have been widely used in several domains. The FSE procedure, as detailed previously in a study [22], involves a two-stage rating system. The first-stage rating system is represented as: vFSC = (vFSC1, vFSC2, vFSC3, vFSC4, vFSC5, vFSC6, vFSC7), whereas the second-stage rating system can be defined as: vFSC1=vFS11-vFS13, vFSC2=vFS21-vFS24, vFSC3=vFS31-vFS33, vFSC4=vFS41-vFS43, vFSC5=vFS15-vFS53, vFSC6=vFS61-vFS63, vFSC7=vFS171-vFS73.

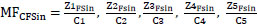

The factor for the fuzzy evaluation is based on the outcome of EFA; 21 factors were classified into seven constructs. Various factors identified were subjected to an assessment index system, as vFS1= (vFS11, vFS12, vFS13,……,vFS7=(vFS71, vFS72, vFS73). The second level possesses the factor itself (FH). The input system belongs to the first and second levels as vFSi. The membership was finalized for each factor and its sub-factors (first level). The membership function ranges from 0 to 1. A five-point Likert scale, ranging from 1 (strongly disagree) to 5 (strongly agree), was used. The membership function together provides a criticality denoted by C= (1,2,3,4,5), where C1 indicates “strongly disagree” and C5 indicates “strongly agree.” Equations (1) to (9) may be used to derive the overall criticality using the membership function based on the collected responses. Thus, for each factor, FSin may be obtained using Equation (1):

|

(1) |

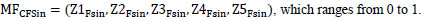

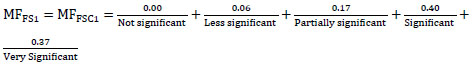

n is the nth factor of a given FSi (i=cFSC1, cFSC2, cFSC3, cFSC4, cFSC5, cFSC6, cFSC7); Z1Fsin/C1 may be termed in percentage as a proportion and ZjFsin (j=1,2,3,4,5). On substituting the membership function, it may be derived using Equation (2) as:

|

(2) |

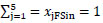

Thus, Equation (3) is represented as:

|

(3) |

Based on respondents’ evaluations (i.e., 0.00%, 0.06%, 0.17%, 0.40%, and 0.37%), FS1 may be used in Equation (1). Consequently, Equation (4) becomes:

|

(4) |

Thus, MFCFSin= (0.00,0.06,0.17,0.40,0.37) may be considered.

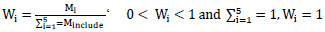

Similarly, weighing the functions of factors is an essential step to determine the effect of each factor. The following equation (5) may be used for weighting:

|

(5) |

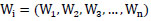

Where, the weighting Winclude is the function of the factor (FS) and factor construct (FSC) I, Minclude is the mean score of FS and FSCinclude obtained from the responses. The weighting of the set may be represented as Equations (6) and (7):

|

(6) |

|

(7) |

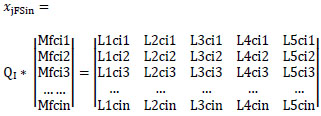

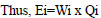

Various stages of MFC constitute FSE. The fuzzy matrix Ei (Equation 8) may be obtained using a weighting function set, i.e., Wi= (W1, W2, W3…Wn) as per Equation (6).

|

(8) |

Where, Ei represents the product of the weight of factor (FS) and rating (Qi)

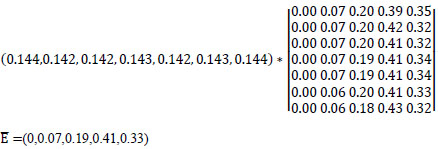

Similarly, we can obtain Equation (9) as:

|

(9) |

A sample calculation for the first factor is presented below as:

|

|

Where 1 ≤ CLinclude ≤ 5

CLoverall= (0,0.07,0.19,0.41,0.33) * (1,2,3,4,5)

CLoverall= (0,0.07,0.19,0.41,0.33) * (1,2,3,4,5)

CLoverall= (0,0.07,0.19,0.41,0.33) * (1,2,3,4,5)

Table 3 presents the weightings and membership functions (MFs) for the factors (FSs) and factor constructs (FSCs) based on FSE.

| Factor code | Weighting of FS | Weighting of FSCs | MF of each F at level 3 | MF of each FSC at level 2 | CL for FSC | MF of each FSC at level 1 | Overall Criticality Level (OCL) |

|---|---|---|---|---|---|---|---|

| FSC1 | 0.144 | (0,0.07,0.19,0.41,0.33) | 4.02 | (0.00,0.07,0.19,0.41,0.33) | 4.00 | ||

| FS1 | 0.339 | (0.00,0.06, 0.17,0.40,0.37) | |||||

| FS2 | 0.336 | (0.00,0.08,0.15,0.40,0.36) | |||||

| FS3 | 0.325 | (0.00,0.05,0.28,0.36,0.30) | |||||

| FSC2 | 0.142 | (0.07,0.2,0.42,0.32,3.98) | 3.98 | ||||

| FS21 | 0.336 | (0,0.06,0.21,0.37,0.35) | |||||

| FS22 | 0.332 | (0,0.08,0.15,0.49,0.28) | |||||

| FS23 | 0.331 | (0,0.05,0.25,0.39,0.31) | |||||

| FSC3 | 0.142 | (0.07,0.2,0.41,0.32,3.97) | 3.97 | ||||

| FS31 | 0.337 | (0,0.07,0.18,0.42,0.33) | |||||

| FS32 | 0.332 | (0,0.09,0.16,0.45,0.3) | |||||

| FS33 | 0.331 | (0,0.05,0.26,0.37,0.31) | |||||

| FSC4 | 0.143 | (0.07,0.19,0.41,0.34,4.01) | 4.01 | ||||

| FS41 | 0.338 | (0,0.06,0.17,0.39,0.37) | |||||

| FS42 | 0.330 | (0,0.08,0.16,0.47,0.29) | |||||

| FS43 | 0.332 | (0,0.05,0.24,0.36,0.34) | |||||

| FSC5 | 0.142 | (0.07,0.2,0.42,0.31,3.97) | 3.97 | ||||

| FS51 | 0.338 | (0,0.07,0.18,0.39,0.35) | |||||

| FS52 | 0.337 | (0,0.08,0.14,0.49,0.3) | |||||

| FS53 | 0.326 | (0,0.06,0.28,0.39,0.27) | |||||

| FSC6 | 0.143 | (0.06,0.2,0.41,0.33,4) | 4.00 | ||||

| FS61 | 0.336 | (0,0.08,0.19,0.36,0.37) | |||||

| FS62 | 0.334 | (0,0.06,0.15,0.5,0.29) | |||||

| FS63 | 0.330 | (0,0.05,0.27,0.36,0.32) | |||||

| FSC7 | 0.144 | (0.06,0.18,0.43,0.32,4.02) | 4.02 | ||||

| FS71 | 0.340 | (0,0.06,0.14,0.44,0.36) | |||||

| FS72 | 0.334 | (0,0.06,0.16,0.47,0.3) | |||||

| FS73 | 0.326 | (0,0.07,0.24,0.38,0.31) |

As mentioned in Table 3, the seven factors along with it CL, namely Organizing and Planning (4.02), Chemical Hazard Identification (3.98), Risk Evaluation (3.97), Control Measures (4.01), Development of Safe Activity Procedures and Provision of Training on Control of Chemical Hazards (3.97), Creation of a Comprehensive Plan that Includes All Procedures, Controls, and Emergency Response Actions (4.00), and Regular Inspection of the Site to Ensure Control Measures are Effective and Adhered to (4.02), demonstrated a mean CL of 4.0. The maximum CL was 4.02 and the minimum CL was 3.97, resulting in a range of 0.05, indicating very low variability; thus, it may be concluded that hospital administration provides consistent management performance across all factors.

5. DISCUSSION

Many chemicals are used in hospitals for cleaning, sterilizing, research, medicinal, and diagnostic purposes. The present study evaluated the risk factors associated with health and safety practices for managing hazardous chemicals in Saudi hospitals using the FSE method. Various factors responsible for managing hazardous chemicals in hospitals were identified using an empirical study. Based on the responses, seven main factors were identified, namely organizing and planning, chemical hazard identification, in-situ inquiry of possible hazards in chemical handling by professional staff, control measures, developing safe activity procedures, providing training on controlling chemical hazards, creating a comprehensive plan that includes all procedures, controls, and emergency response actions, and regularly inspecting the site to ensure control measures are effective and adhered to. The overall critical level (OCL) was measured considering a two-stage risk rating using FSE. The OCL of the factors, as determined by the FSE approach, was 4.0, meaning that they must be addressed to improve health and safety procedures in the handling of hazardous chemicals in hospitals.

‘Organizing and Planning’ plays a significant role in managing hazardous chemicals in hospitals [23]. This study provides a foundation for averting risks in managing hazardous chemicals. In this case, the critical level was found to be 4.02, indicating that good performance exists for well-structured management. The risk assessment and its management may vary depending on the location of hazardous chemicals within the hospital setup. An expert team may provide the right solution. The factor “Chemical Hazard Identification” plays an important role in identifying hazardous chemicals. In the present study, the CL was found to be 3.98, indicating moderate performance. Additionally, it also indicates some gaps in chemical hazard identification. The third factor, Risk Evaluation, was assessed to identify the risk level [12]; in the present study, the CL of “Risk Evaluation” was found to be 3.97, indicating moderate performance. It also indicates that the risk evaluation plan may be revisited to refine then. The fourth factor, Control Measures, provides a control-based solution for managing hazardous chemicals [12]. In the present study, the CL was found to be 4.01, indicating good performance, which shows that adequate risk control is in place. The fifth factor, developing safe activity procedures and providing training on controlling chemical hazards, provides a systematic approach to managing various activities involving hazardous chemicals. In the present study, the CL was found to be 3.97, indicating moderate performance, suggesting that staff training or procedural clarity might need enhancement. Handling hazardous chemicals in accordance with safety procedures, with adequate training in accident management and first aid, is mandatory [10].

The sixth factor, creating a comprehensive plan that includes all procedures, controls, and emergency response actions, provides a systematic approach to handling hazardous chemicals. This includes standard operating procedures (SOPs) and a plan to avert any hazardous chemical-based mishaps in hospitals [24]. In the present study, the CL was found to be 4.00, indicating good performance, as it suggests that the strategies and plans for the hospital in managing hazardous chemicals are sound. The seventh factor, regularly inspecting the site to ensure that control measures are effective and adhered to, ensures that safe and healthy practices prevail without any accidents occurring while handling hazardous chemicals in the hospital. In the present study, the CL was found to be 4.02, indicating good performance. This also suggests that ongoing compliance efforts are strong in ensuring the safe handling of hazardous chemicals.

The extreme environmental conditions of Saudi Arabia, especially during the summer, may result in temperatures that exceed 40°C (104°F). Therefore, it is crucial to install a proper ventilation system and address storage needs to minimize chemical volatility. Several strategies may be planned and adopted to manage hazardous chemicals in Saudi hospitals. Preferred strategies, such as environmental monitoring and biological monitoring, may be implemented [12].

CONCLUSION

The present study identifies seven factors to manage and handle hazardous chemicals in the hospital, aiming to prevent mishandling or accidents that could result from improper handling of these chemicals. All hospital professionals must be provided systematic exposure to such factors to understand the significance of each factor in controlling any critical mishap. Additionally, all seven factors can be systematically controlled by providing knowledge and training to enhance the skills and understanding of medical professionals. Eliminating or reducing hazards can be most effectively achieved through the implementation of engineering measures, administrative policies, and the use of personal protective equipment (PPE). The regular training and practical camps may help enhance the awareness of hospital professionals in handling hazardous chemicals.

AUTHORS’ CONTRIBUTIONS

The authors confirm their contribution to the paper as follows: A.S.M.A., K.M.Q., and M.R.N.M.Q.: Conceptualization; A.S.M.A., K.M.Q., and M.R.N.M.Q.: Methodology; A.S.M.A., K.M.Q., and M.R.N.M.Q.: Formal analysis, A.S.M.A., K.M.Q., and M.R.N.M.Q.: Writing review and editing;. All authors have read and agreed to the published version of the manuscript.

LIST OF ABBREVIATIONS

| CL | = Critical level |

| FSE | = Fuzzy Synthetic Evaluation |

| F1 | = Formula One |

| DMs | = Decision-makers |

| FSCs | = Factor Constructs |

| MFs | = Membership Functions |

| OCL | = Overall Critical Level |

| SOPs | = Standard Operating Procedures |

| PPE | = Personal Protective Equipment |

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Ethics approval for this study was obtained from the Research Ethics Committee of the Industrial Engineering Department, King Khalid University, Saudi Arabia, vide KKU/0012/2024 dated 23rd December, 2024.

HUMAN AND ANIMAL RIGHTS

All procedures performed in studies involving human participants were conducted according to the ethical standards of institutional and/or research committees and in accordance with the 1975 Declaration of Helsinki, as revised in 2013.

CONSENT FOR PUBLICATION

Written informed consent has been obtained from the respondents in this study.

AVAILABILITY OF DATA AND MATERIALS

All the data and supporting information are provided within the article.

ACKNOWLEDGEMENTS

The authors would like to extend their appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia.